ARGUS Smart-Connected Technologies (SCT)

Optimize your Strander in Real-Time

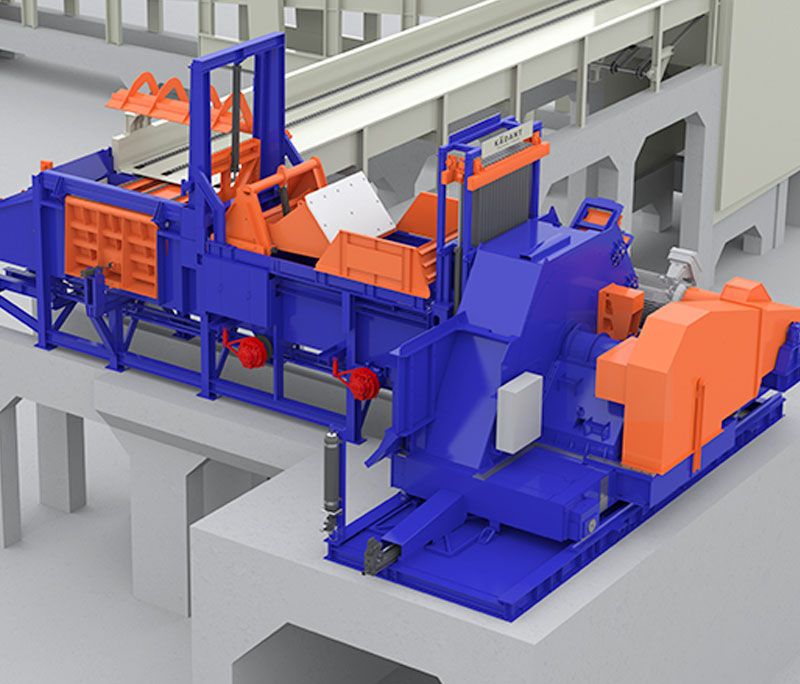

ARGUS Smart-Connected Technologies (SCT) was developed by Kadant Carmanah, to provide OSB producers with the data they need to produce better quality strands, improve strander production, and prevent unexpected downtime.

How ARGUS Works

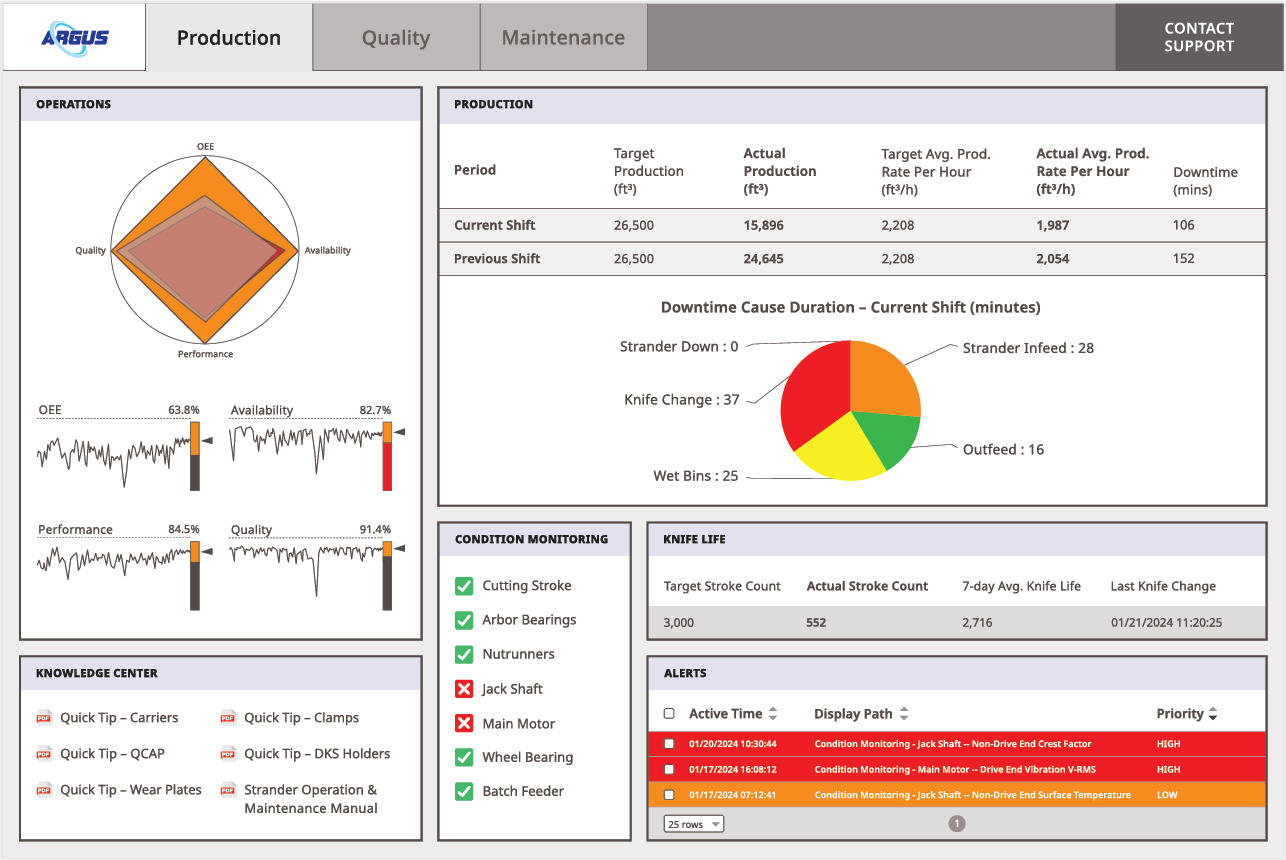

This innovation combines 3 different proprietary systems to deliver the metric for Overall Equipment Effectiveness (OEE) at the strander, so that wood room operators and management can make more informed decisions about how to optimize their stranding operation in real-time.

Live dashboards and reporting deliver accurate trending for throughput, uptime, and quality at the strander.

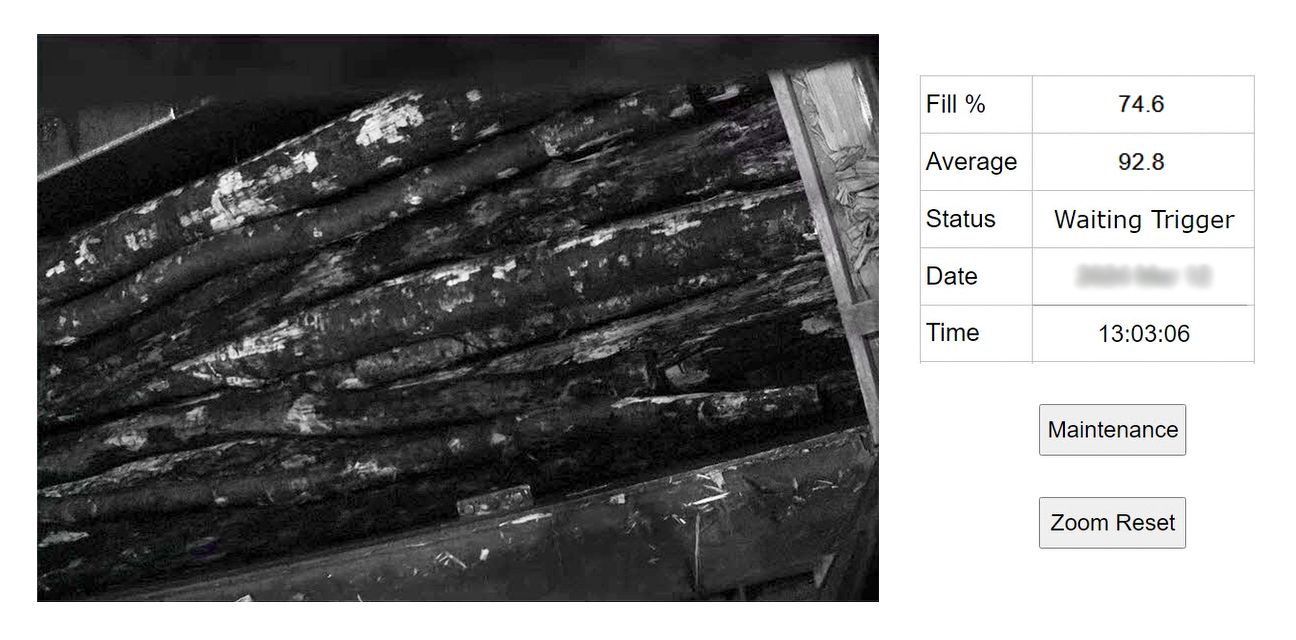

System 1: ARGUS Log Fill Optimizer (LFO)

ARGUS LFO is a vision system that scans the log fill level at the strander infeed, measuring the amount of wood the strander consumes in real-time. OSB mills can now modify their infeed for higher fill rates, increased throughput, and improved operational efficiency.

OEE METRIC UNLOCKED: PERFORMANCE

System 2: ARGUS Condition Monitoring & Intelligence (CMI)

ARGUS CMI combines existing Strander PLC tags with a series of condition monitoring sensors that have been installed across all strander components and assemblies, to collect and analyze data-driven insight about how the strander is operating in real-time. OSB mills can now identify bottlenecks at the strander and detect equipment anomalies in real-time, and take immediate action to avoid unexpected downtime.

OEE METRIC UNLOCKED: AVAILABILITY

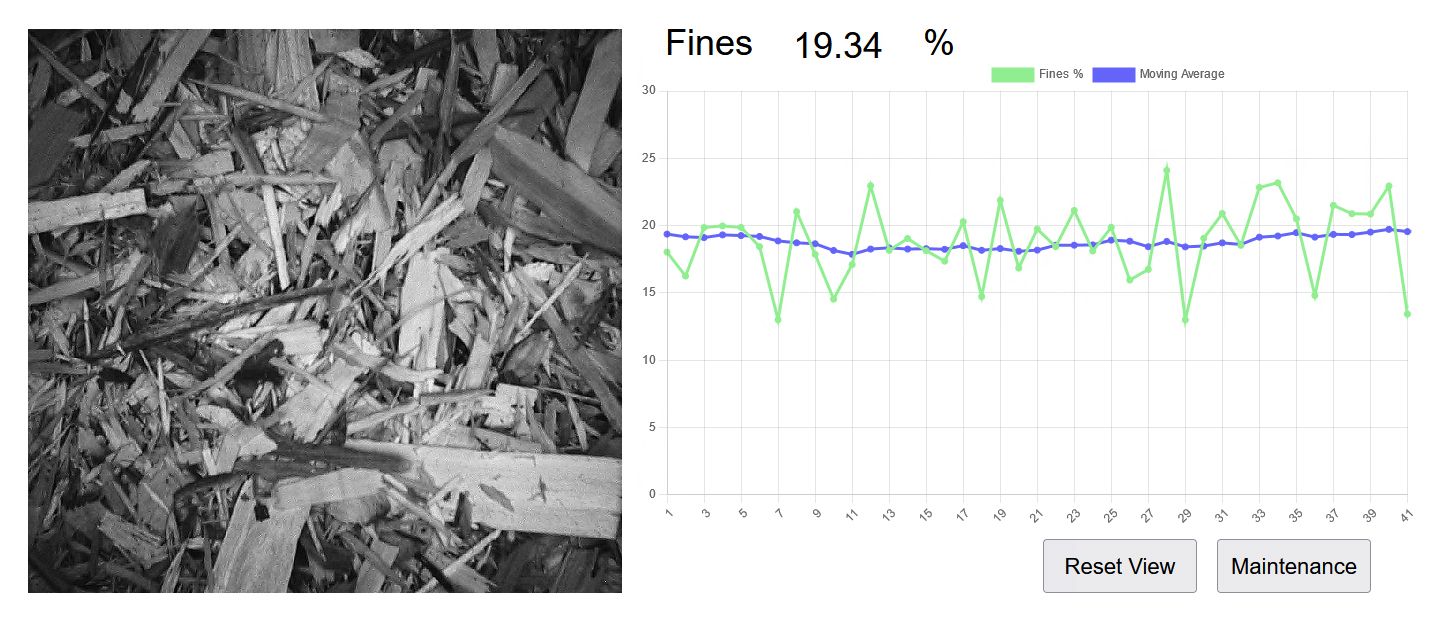

System 3: ARGUS Fines Measurement System (FMS)

ARGUS FMS is a vision system that continuously scans the strander outfeed conveyor to provide real-time fines percentages for every cutting pass. By automating the strand sampling process in real-time, this removes the variability and bias associated with inconsistent and infrequent strand collection procedures currently done by hand. With access to a far greater number of accurate strand samples, OSB producers can now make more informed process improvement decisions in real-time.

OEE METRIC UNLOCKED: QUALITY

Benchmark strander performance across multiple operators, shifts, lines, or mills.

Developed and Supported by the Global Leaders in Strand Technology

Kadant Carmanah are stranding process experts focused on the OSB market. We’ve learned by listening to our customers and being responsive to their needs, to help them improve the efficiency, consistency, and quality of their strand output.

To put it simply: you will not find another strand technology manufacturer to partner with, who can match our commitment, experience, and successes within the global OSB market.

Included with Every ARGUS SCT Subscription:

Secure Data Collection

- Combined in one centralized database

- Secure transmission & storage

- Built-in data encryption & security

Condition Monitoring

- Define thresholds

- Detect anomalies in real-time

- Take immediate action

Service & Support

- In-depth consultation to define targets

- Remote anomaly detection

- Regular check-ins & reviews

Accurate Reporting

- Graphs & reports are personalized to your goals

- Easy-to-understand with visuals & summaries

- Cloud-based for access on any device

Improved Decision Making:

Increase visibility and transparency across your entire stranding operation.

Maximize maintenance scheduling to avoid unexpected downtime.

Prevent critical parts failure with ability to detect warnings and isolate issues.

Monitor operator skill levels to identify which employees need further training.

Improve targeting and forecasting with less variability and minimal downgrade.

Optimize productivity and efficiency to yield quality strands at high throughput.