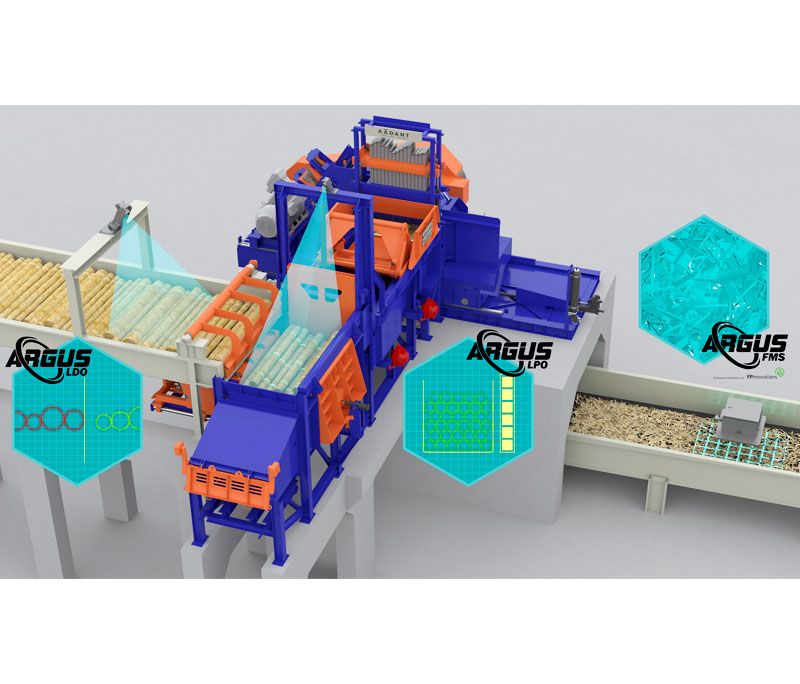

SmartRING Strander

The SmartRING strander cuts tree length or batch fed logs into strands for OSB production.

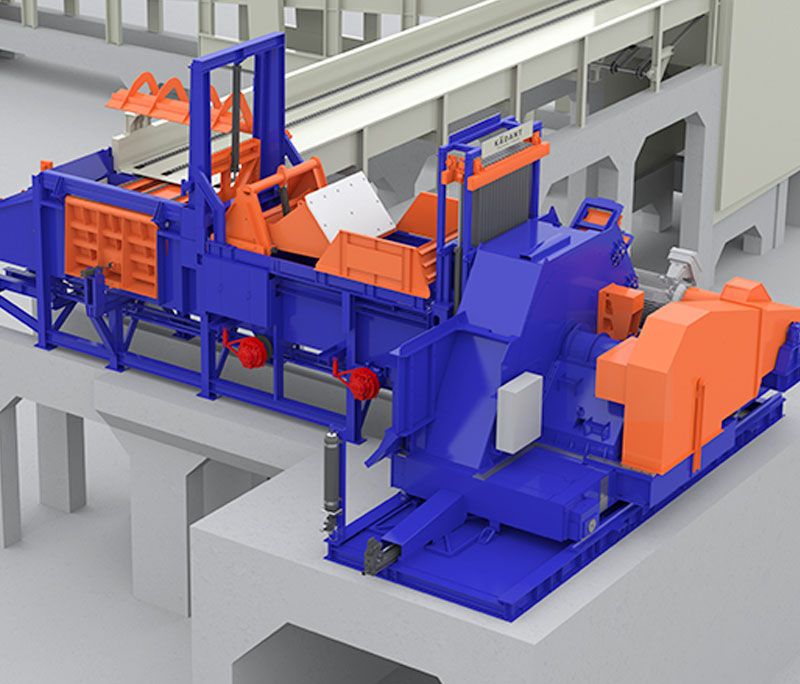

An innovative clamping system secures the logs in place while the carriage mounted strander extends into the cutting chamber. Knives, mounted within the inner periphery of the ring, strand the logs contained within the chamber. At the end of the cutting cycle, the carriage automatically returns to the initial position to repeat the sequence. The knives are designed to extend to the outer edge of the precision ground ring, allowing the ring to advance through the batch of logs during stranding while maintaining consistent strand thickness.

Every detail of the SmartRING stranders has been engineered for efficient, economical production of high quality strands. All critical wear components are designed to be easily replaced, utilizing an engineered modular system. This eliminates the added cost and downtime of regrinding and shimming.

Available Sizes:

- 28/81 Gen 1

- 32/88 Gen 1

- 28/75 Gen 2

- 32/98 Gen 2

Features

Feedback control linked to the strander rings RPM with real-time forward motion adjustment

- Knife change procedure using a highly automated nutrunner system

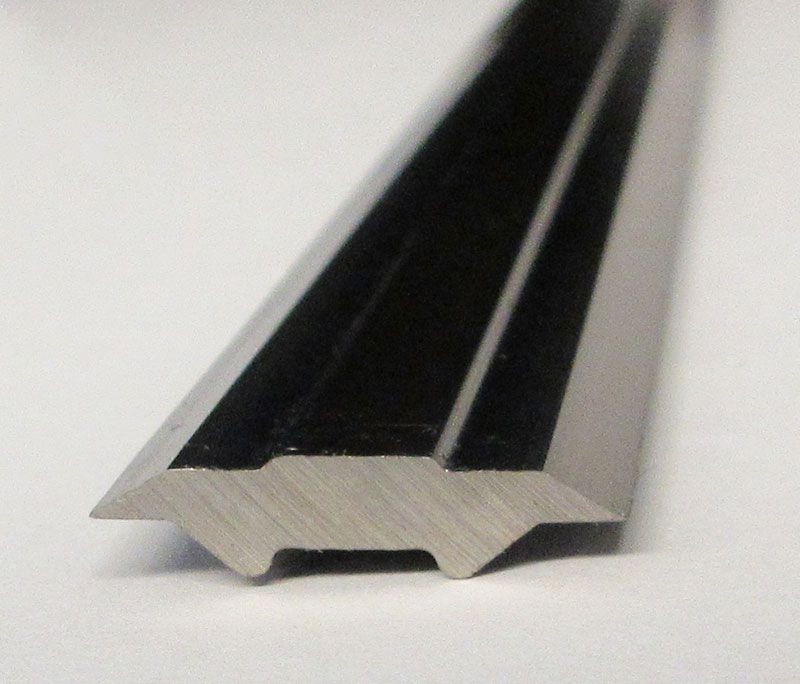

- Disposable knife system

- Patented ring removal system

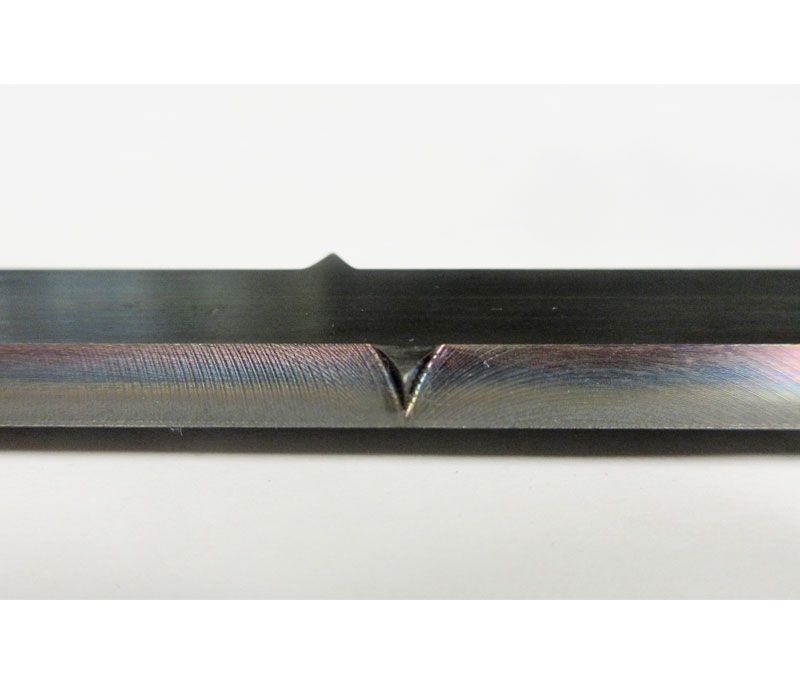

- Bend-away anvil

Benefits

- Consistent strand quality

- Immediate feedback to operator

- Reduced likelihood of improperly installed knives

- Improved strand quality and elimination of the need for a grinding room with its associated costs

- Change-out of entire ring in less than 10 hours

- Maximized safety of the machine