Our History

The Early Years – Allan and McKelvie Engineering

In 1913, two young men joined forces to establish Allan and McKelvie Engineering Company, located on Pender Street in downtown Vancouver.

George Allan and Alex McKelvie’s goal was to provide repair work to the maritime and food industries that dominated the scene. Then in 1914, the first World War changed their plans.

The young men shifted gears to assist the war efforts by designing and manufacturing components for warships and freighters. Allan and McKelvie gained the reputation of being a reliable supplier of quality products and their business started to grow.

Canadian Sumner Iron Works

After the war, men shifted their focus to the modern machinery of the burgeoning forest industry. They succeeded in forming a partnership with the most prominent supplier in forest machinery: Sumner Iron Works of Everett, Washington.

By 1919 their joint venture, Canadian Sumner Iron Works (CSIW), was manufacturing and selling equipment designed by the U.S. firm out of the original Vancouver site. By the 1920s, Sumner machinery was nationally recognized for producing high quality lumber and was being bought by every lumber producing country in the world.

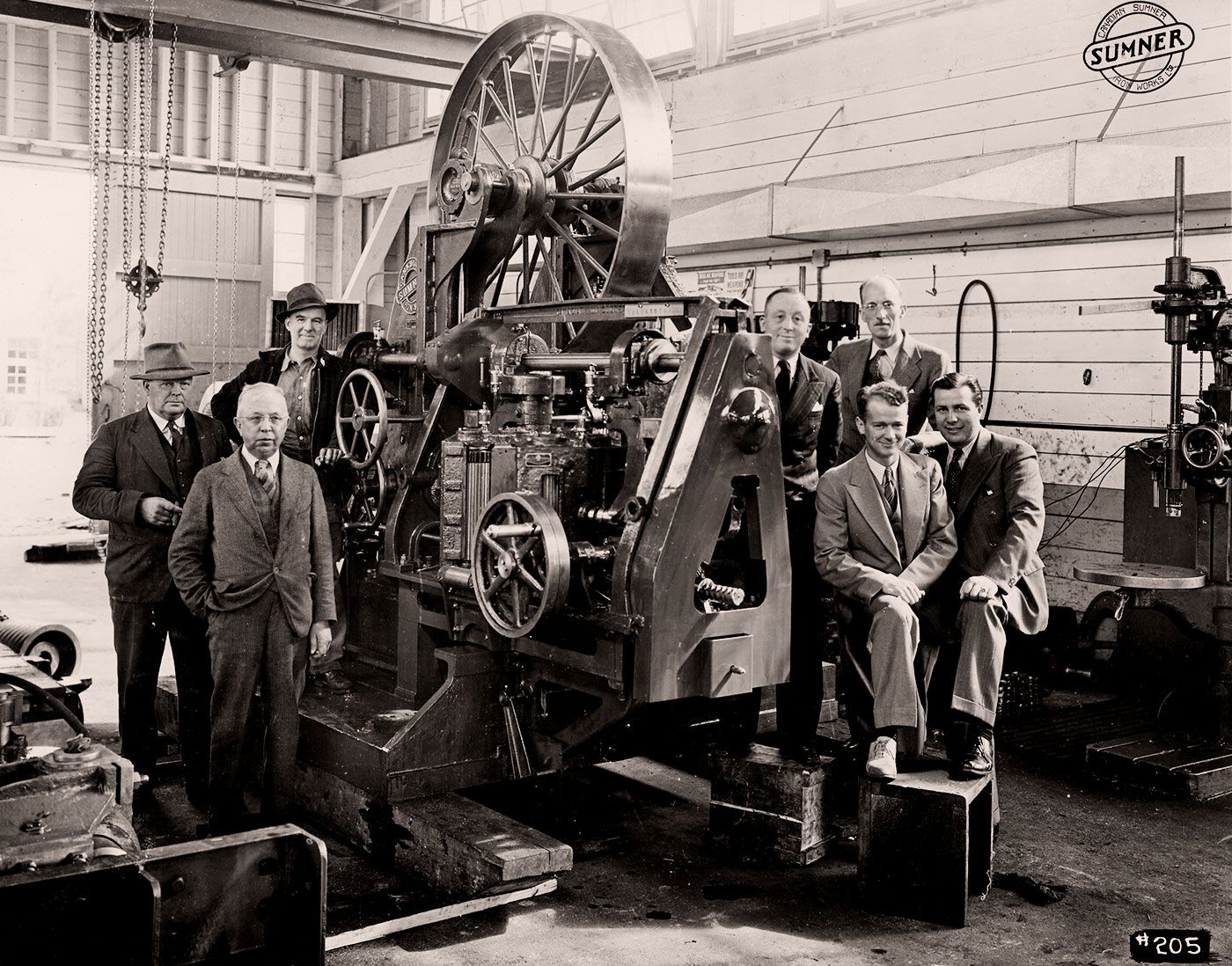

William Gait and the “Sumner Men”

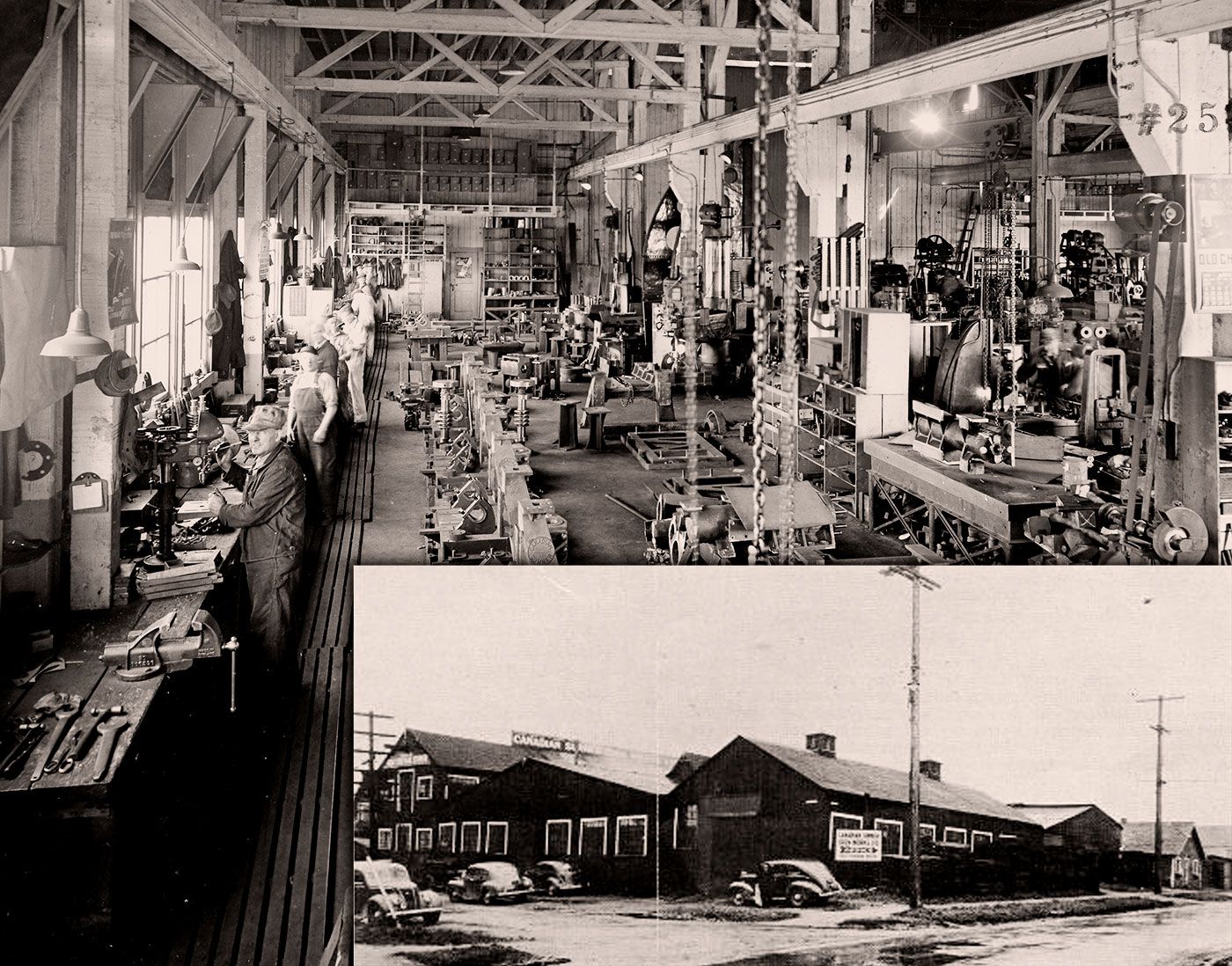

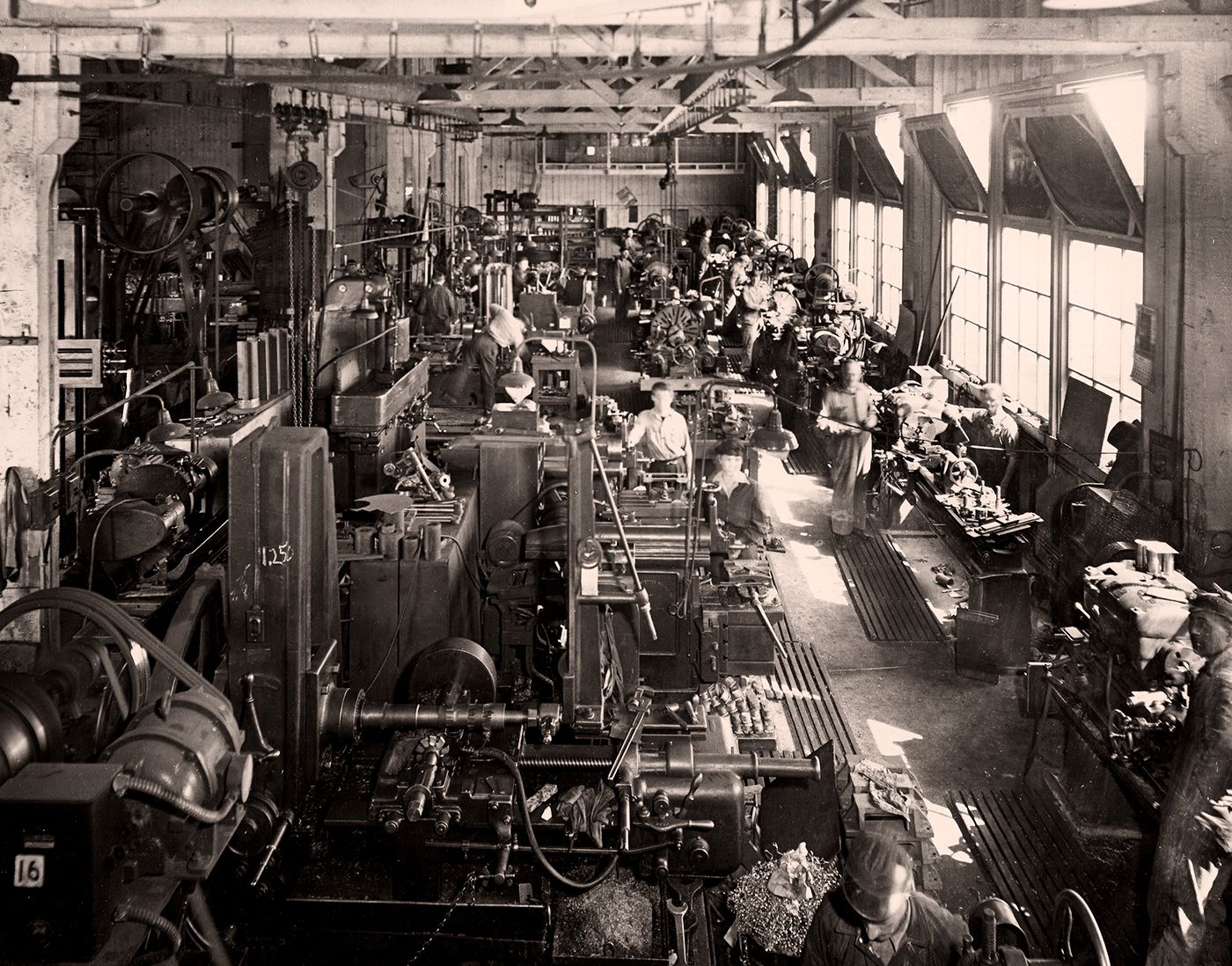

New markets and increased sales created additional demands. The plant was expanded to meet design and manufacturing needs.

Responsible for the change was William “Willie” Gait, who joined CSIW in 1919 and pioneered the apprenticeship program that still continues today. The program is responsible for the development of thousands of trade apprentices. Gait, along with George Allan, considered the employees to be one big family, with the apprentices taking the role of sons. The sons were expected to realize that their responsibility as “Sumner Men” did not end at the plant gates.

The Depression Era

The Depression brought many problems that led to reduced sales and layoffs. To survive, Sumner began designing pulpmill machinery. By the early 1930s their machinery was well known and the company was highly respected in this segment.

Foundry markets expanded and so did the demand for new equipment. In 1931, CSIW bought eight acres of industrial land on Vancouver’s east side that had good access to the railway and waterfront.

Because of the business climate, the new plant could not be built immediately. It was nine years later, when the second World War was underway that CSIW erected an office, foundry, and two machine shops and relocated the Pender Street location to a new site.

The Rebirth of the Shipping Industry

The Second World War brought an abrupt end to the lingering effects of the Depression, and the need to transport men and supplies once again across the Atlantic spurred the rebirth of the West Coast shipping industry.

As it had in the first war, CSIW turned circumstances to its advantage and geared its production to the new Canadian ships needed for the war. By the end of the war, the Royal Canadian Navy found itself as the world’s third largest navy with 471 ships, mostly built in Canadian factories.

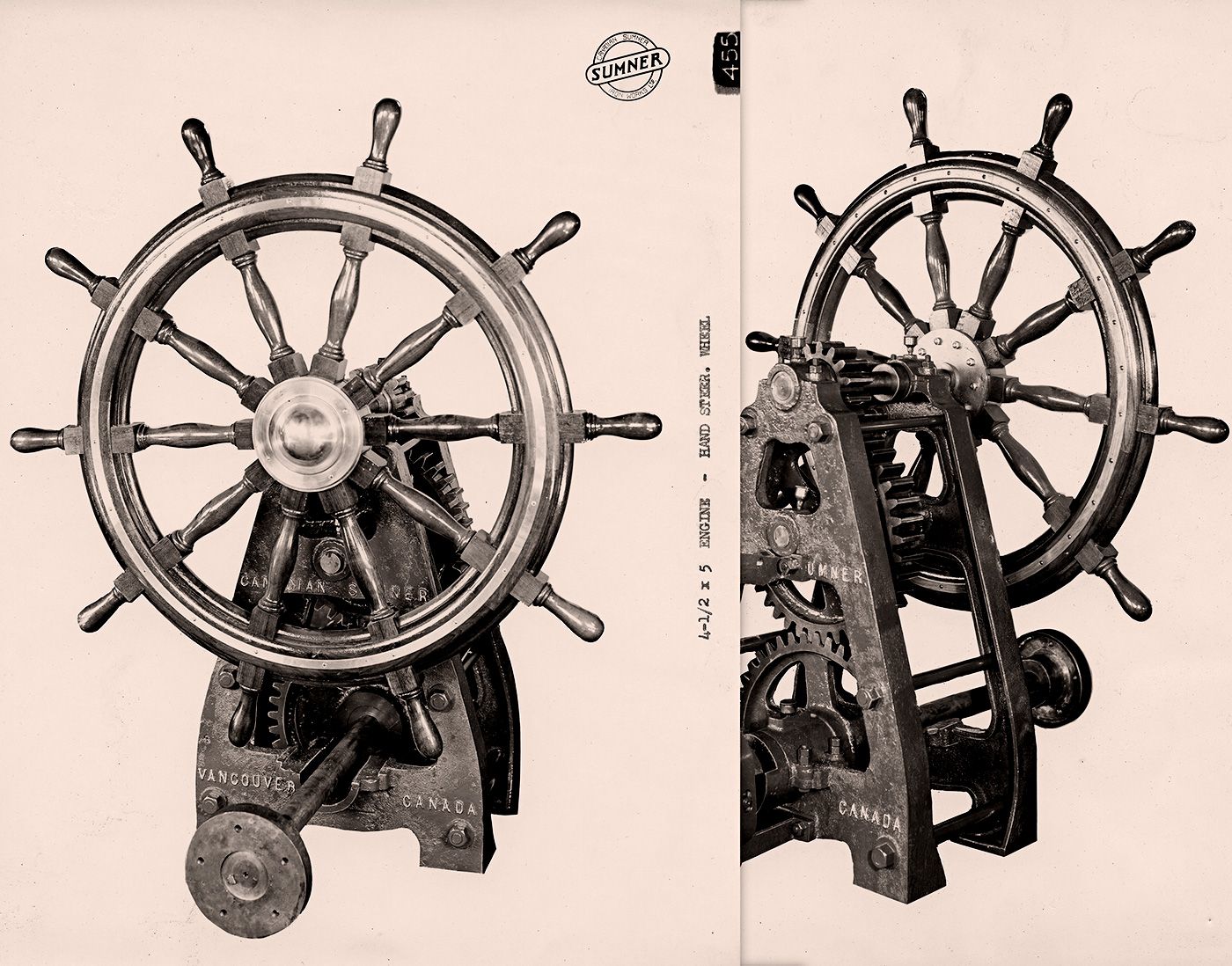

Praise for Steering Gears

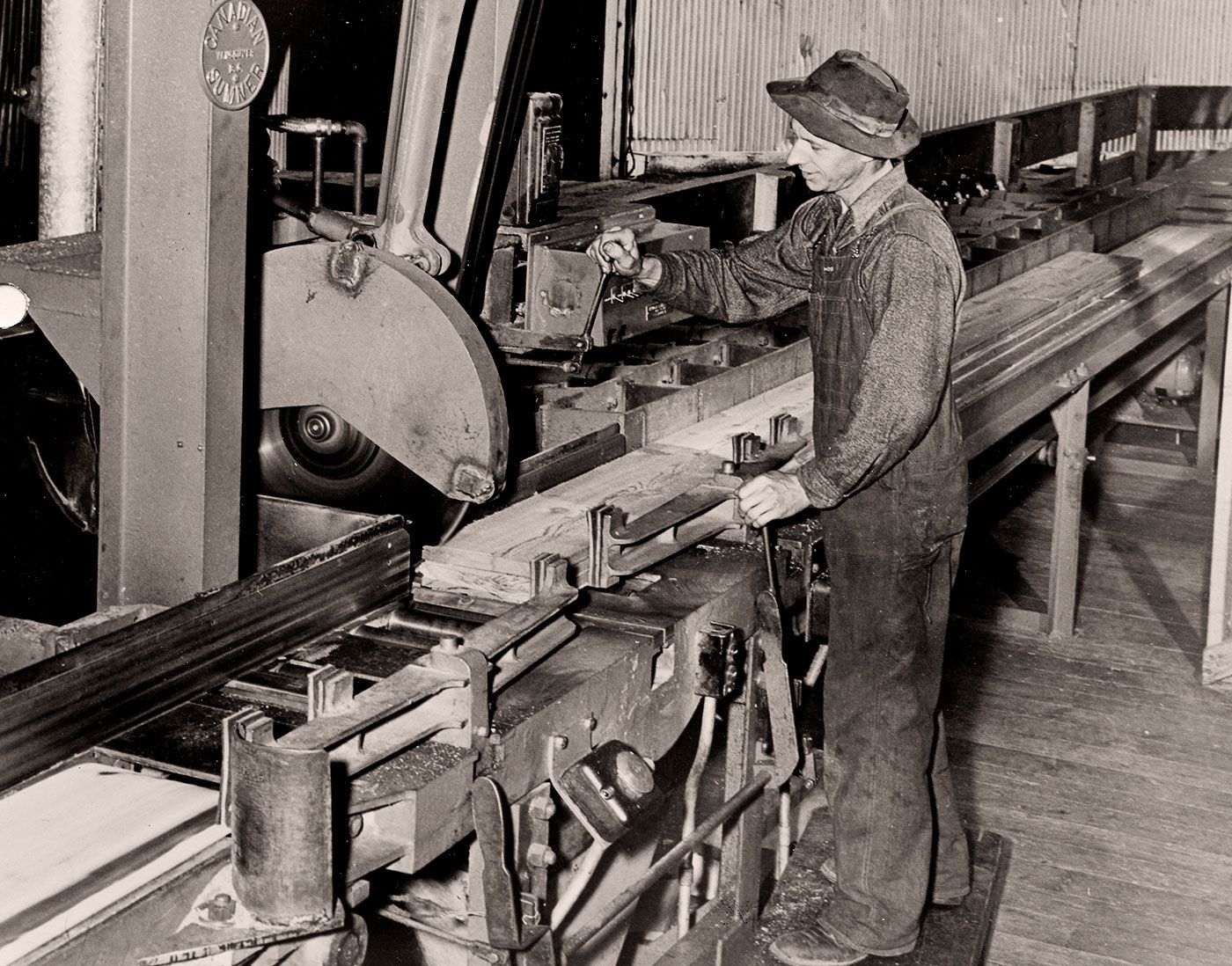

The company’s first order was to supply steering gear engines for the warship known as the Corvette. The first order was soon followed by an order for steam and hand steering gear for Canadian-built minesweepers.

The quality of its products was praised in 1944 by The Shipping Register magazine which reported of the company, “Their standard of workmanship is high, of which they are justifiably proud. Because of this, the demands that have been made upon them during the present war have been very great and orders from shipyards building the new frigates on both the St. Lawrence and the Pacific Coast have been awarded to them.”

Post War Recovery

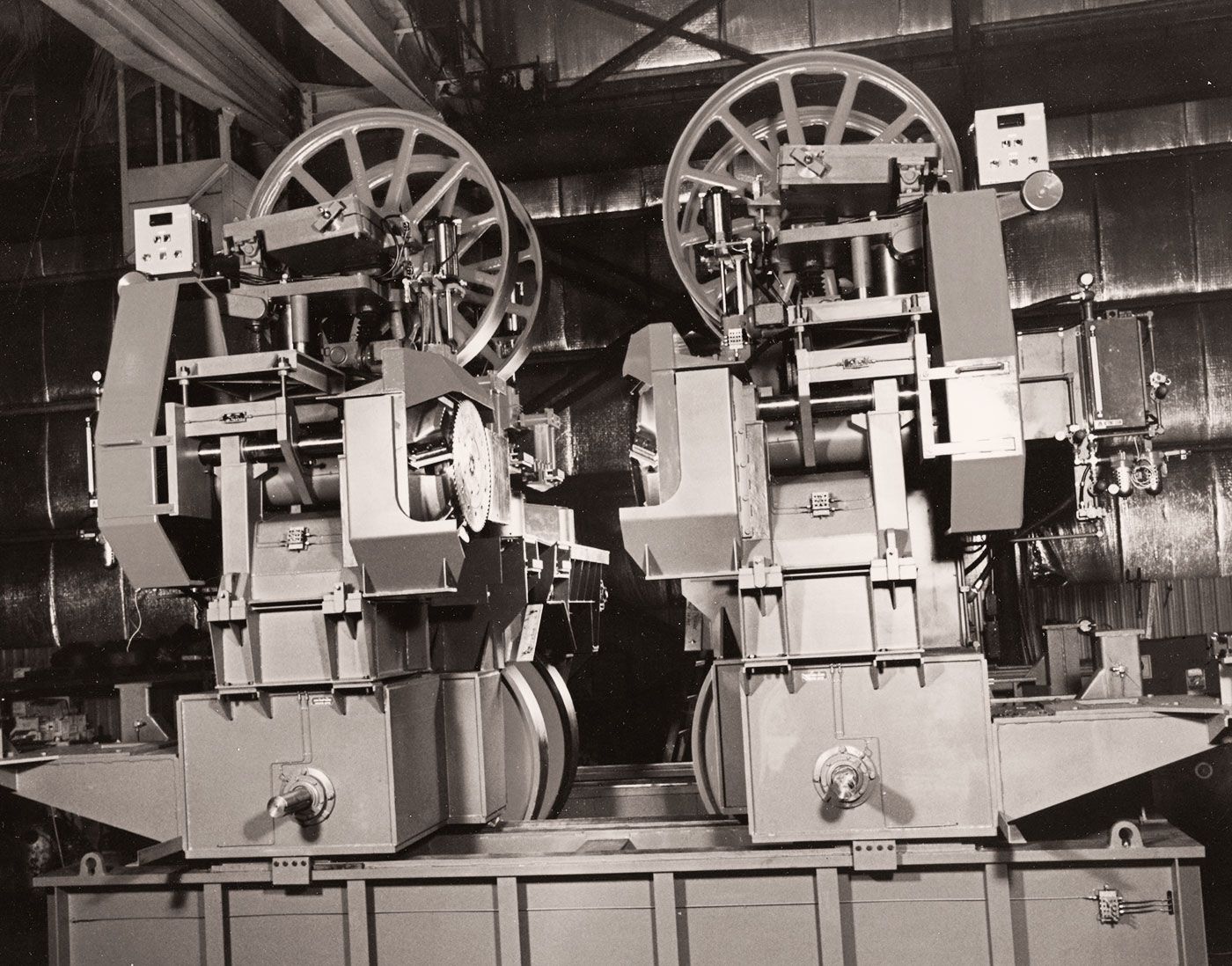

With the end of the Second World War, CSIW shifted back to serve the needs of domestic industries. Sumner engineers embarked on a research and development program to upgrade forest products machinery.

With the western Canadian economy booming, numerous modern sawmills and pulpmills were being built. CSIW became a major supplier to this region as well as international locations. By the 1950s, Sumner was enjoying expanded sales, buildings, and machinery.

The Making of a Public Company

In 1952 Norman Perry succeeded George Allen as president and general manager. He led the initiative to move the company from private to public and eventually acquire longtime partner Sumner Iron Works of Everett, Washington

Continuing into the late 1950s, the company became more diversified. During this time, the CSIW foundry became a major supplier of iron castings and developed more components and machinery to serve that market.

The Black Clawson Buyout

In 1958 the western Canadian economy was weakening and CSIW began to suffer. After struggling for a few years, the Sumner plants were bought by Black Clawson in 1962.

A large company with international scope, Black Clawson exposed the Sumner products to a larger market. It expanded the company’s focus to address global markets and increased its production and efficiency.

Black Clawson ownership lasted for just three years. The company had bought Sumner in order to acquire the designs and expertise for woodroom and sawmill machinery. With this objective accomplished it made no sense to have two similar operations within 100 miles of each other and in 1965, the Vancouver plant was sold to CAE Industries.

CAE Machinery Weathers the Recession

The Vancouver plant – renamed CAE Machinery – allowed the company to diversify its focus and participate in the western Canadian economy. Experienced employees had been lost under Black Clawson ownership, and there was an agreement which excluded CAE from selling into the U.S. market for a period of time. Under these circumstances it took new management nearly two years to get the plant back on its feet.

In the 1970s business continued to grow, and CAE became a major supplier to domestic forest industries. New management introduced a more aggressive business approach and brought a renewed energy and enthusiasm that served the company well in the coming recession on 1981. While many companies were floundering, CAE Machinery had modern facilities, an experienced management group and workforce, and proven product lines.

Carmanah Lands in Surrey, B.C.

In 2003, CAE Industries made a strategic decision to focus on their core business – Aircraft Flight Simulation – and divested their business operations in other sectors, including the CAE Machinery plant. Birch Hill Equity Partners purchased CAE Machinery Ltd. in mid-2003. They named the new company Carmanah after the pristine and protected Carmanah Valley, located on Vancouver Island, British Columbia. In August 2011, Carmanah relocated its offices, manufacturing, and warehousing facilities to its present location in Surrey, B.C.

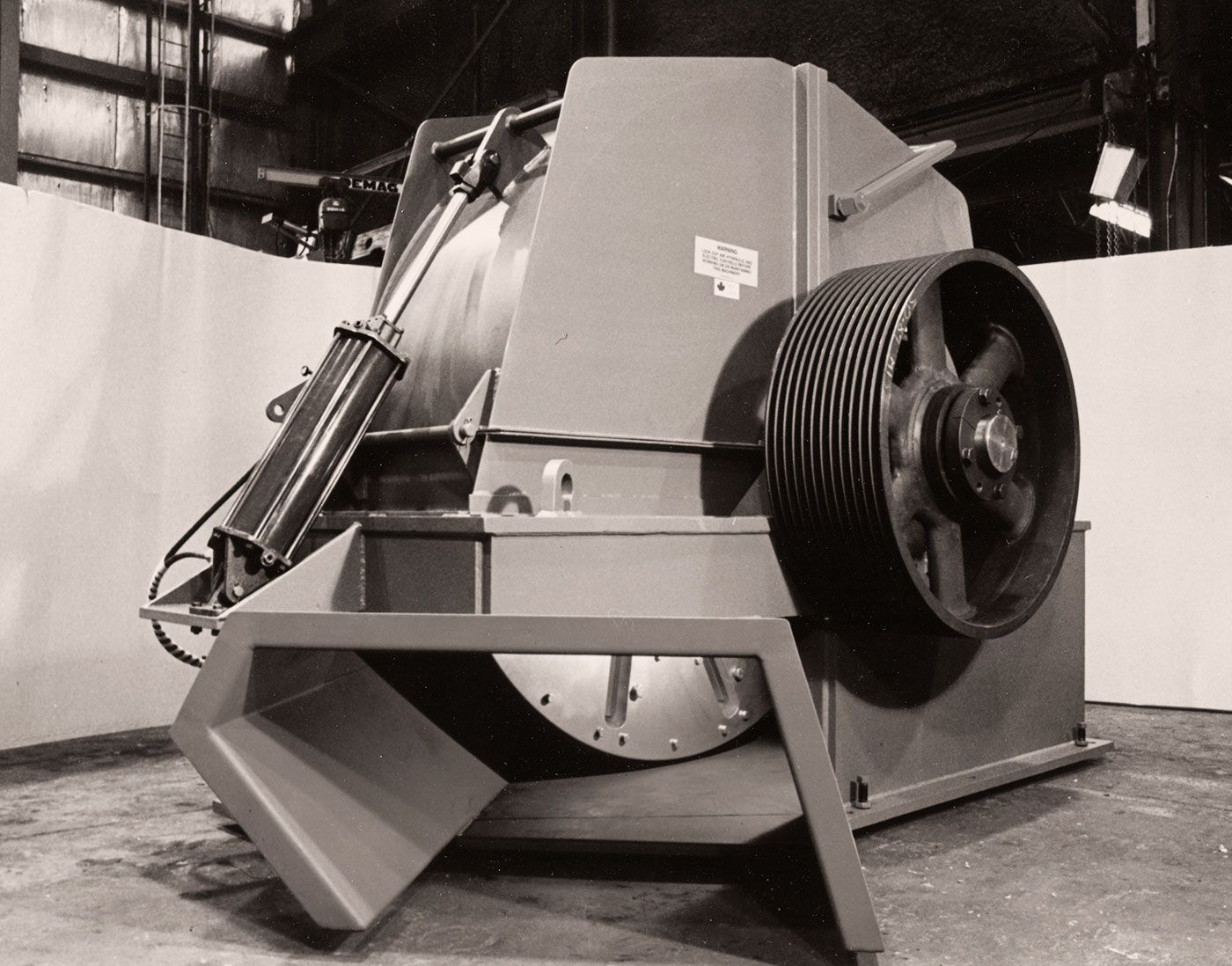

Since 2003, the company has continued to evolve with new product development and innovation. The acquisition of the Nicholson chipper business in 2005 expanded the company’s product range for the pulp, sawmill, and biomass industries. In 2012, Carmanah launched a successful disposable knife business for OSB production.

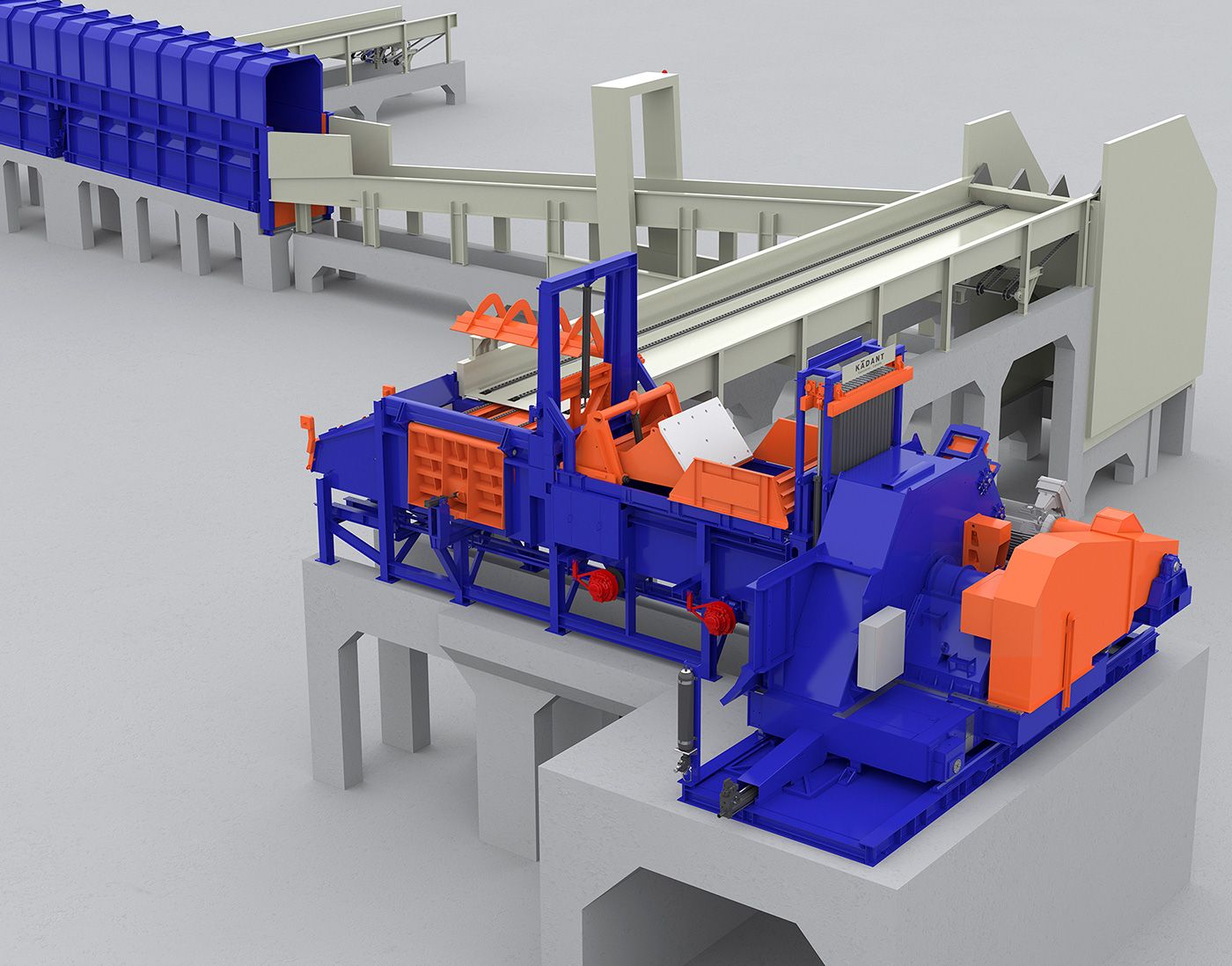

The Future of Kadant Carmanah

Under its current ownership by Kadant Inc., based in Westford, Massachusetts, Kadant Carmanah continues to strengthen its position as a world leader in stranders and related equipment, debarkers, and wood chipping equipment.